Large Tonnage Tablet Press Installation and Alignment Procedures: A Technical Guide

Industry Background and Market Demand

The pharmaceutical, nutraceutical, and chemical industries rely heavily on large tonnage tablet presses for high-volume production of solid dosage forms. These machines must deliver consistent compression force, precise weight control, and minimal downtime to meet stringent regulatory standards. With increasing demand for high-speed tablet manufacturing, proper installation and alignment of large tonnage presses have become critical to ensuring operational efficiency and product quality.

Market trends indicate a shift toward automated, digitally integrated tablet presses capable of real-time monitoring and predictive maintenance. Companies investing in large tonnage equipment must prioritize correct setup procedures to avoid premature wear, misalignment, and production delays.

Core Concepts and Key Technologies

Large tonnage tablet presses (typically 50–100 tons or higher) require robust structural support and precise alignment to handle high compression forces. Key components include:

- Main Frame & Platen: The foundation must resist deflection under load.

- Punch & Die System: Ensures uniform tablet density and weight.

- Feeding System: Must distribute powder evenly to prevent capping or lamination.

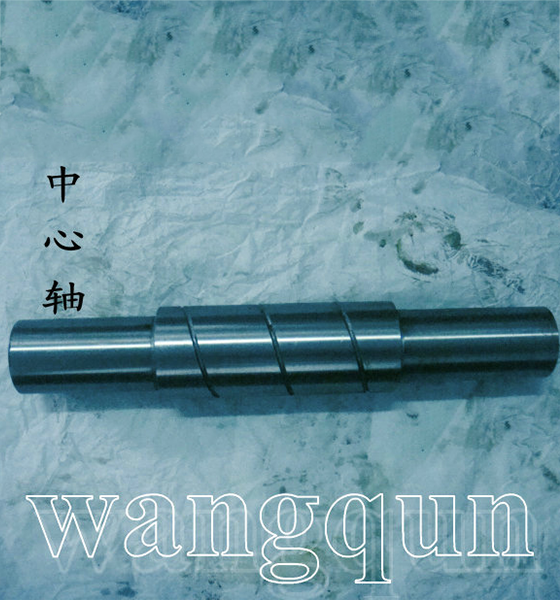

- Compression Rollers & Eccentric Shaft: Transmit force uniformly.

Alignment accuracy is measured in microns, as even minor deviations can lead to tablet defects or machine wear. Laser alignment tools and dial indicators are commonly used to verify parallelism and concentricity.

Structural Design, Materials, and Manufacturing

High-quality tablet presses are constructed from hardened steel alloys to withstand repetitive stress. Critical manufacturing considerations include:

- Precision Machining: Components like platens and rollers require CNC grinding for flatness.

- Thermal Stability: Materials should resist expansion under prolonged operation.

- Modular Design: Simplifies maintenance and realignment.

Hydraulic or servo-electric drives are increasingly replacing mechanical systems for better force control.

Critical Factors Affecting Performance

Several factors influence the efficiency and longevity of a large tonnage tablet press:

1. Foundation Stability: Vibration or settling can misalign the press. Reinforced concrete bases with isolation pads are recommended.

2. Tooling Alignment: Punches and dies must be parallel to prevent uneven compression.

3. Lubrication Systems: Automated oil circulation reduces friction and heat buildup.

4. Environmental Controls: Humidity and temperature fluctuations can affect powder flow and tablet hardness.

Supplier Selection and Quality Standards

When sourcing a large tonnage tablet press, manufacturers should evaluate:

- Compliance with GMP & ISO Standards: Ensures regulatory acceptance.

- Service & Support: Availability of technical assistance for installation and calibration.

- Customization Options: Adaptability for different tablet shapes and materials.

Leading suppliers often provide on-site alignment services to minimize setup errors.

Common Challenges and Industry Pain Points

1. Vibration & Noise: Improper alignment increases mechanical stress.

2. Tooling Wear: Misalignment accelerates punch and die deterioration.

3. Production Delays: Recalibration due to poor initial setup disrupts schedules.

4. Regulatory Scrutiny: Deviations in tablet weight or hardness can lead to batch rejections.

Application Scenarios and Case Studies

A multinational pharmaceutical company recently upgraded to a 75-ton tablet press for extended-release formulations. Post-installation, they experienced excessive vibration due to an unleveled base. After laser realignment and foundation reinforcement, tablet hardness variability dropped by 30%, demonstrating the importance of precision setup.

Current Trends and Future Developments

1. Smart Presses: IoT-enabled sensors monitor alignment in real time.

2. AI-Based Predictive Maintenance: Detects misalignment before failure occurs.

3. Hybrid Drives: Combine hydraulic precision with electric energy efficiency.

FAQ: Large Tonnage Tablet Press Alignment

Q: How often should alignment be checked?

A: Quarterly inspections are standard, but high-speed presses may require monthly verification.

Q: Can misalignment cause tablet defects?

A: Yes, uneven compression leads to capping, sticking, or weight variation.

Q: What tools are used for alignment?

A: Laser alignment systems, dial indicators, and precision levels.

Q: Is operator training necessary for alignment?

A: Absolutely—improper adjustments can worsen misalignment.

Conclusion

Proper installation and alignment of large tonnage tablet presses are non-negotiable for achieving high yields and regulatory compliance. Investing in precision setup, quality tooling, and advanced monitoring systems ensures long-term operational efficiency. As technology evolves, integrating smart alignment solutions will further optimize tablet manufacturing processes.

Copyright © 2025 Changzhou Wangqun Pharmaceutical Machinery Co., Ltd. Все права защищены.

Карта сайтаЭтот веб-сайт использует файлы cookie, чтобы обеспечить вам максимально эффективное использование нашего веб-сайта.

Комментарий

(0)