Disinfection Tablet Press Installation and Setup Guide

Introduction

Disinfection tablets are widely used in water treatment, healthcare, and sanitation to ensure safe and clean environments. A tablet press machine is essential for producing uniform and high-quality disinfection tablets. Proper installation and setup of the tablet press are critical to achieving optimal performance, efficiency, and safety.

This guide provides a step-by-step process for installing and setting up a disinfection tablet press, covering site preparation, machine assembly, calibration, operation, and maintenance.

---

1. Site Preparation

Before installing the tablet press, ensure the workspace meets the following requirements:

1.1 Location Requirements

- Choose a clean, dry, and well-ventilated area.

- Ensure sufficient space for operation, maintenance, and material handling.

- Avoid areas with excessive dust, humidity, or temperature fluctuations.

1.2 Power Supply

- Verify the voltage and frequency requirements of the tablet press (e.g., 220V/380V, 50Hz/60Hz).

- Ensure stable power supply with surge protection to prevent electrical damage.

- Ground the machine properly to avoid electrical hazards.

1.3 Workbench and Support

- Place the machine on a sturdy, vibration-resistant workbench or stand.

- Ensure the surface is level to prevent misalignment during operation.

1.4 Safety Measures

- Keep a fire extinguisher nearby.

- Install emergency stop buttons within easy reach.

- Provide proper lighting for safe operation.

---

2. Unpacking and Inspection

Upon receiving the tablet press, follow these steps:

2.1 Unpacking

- Carefully remove packaging materials to avoid damaging components.

- Check for any visible damage during transit.

2.2 Component Verification

- Refer to the packing list and ensure all parts are included:

- Main machine body

- Punch and die sets

- Hopper and feeding system

- Control panel

- Tooling accessories (wrenches, lubricants, etc.)

- Report missing or damaged parts immediately.

---

3. Machine Assembly

3.1 Mounting the Machine

- Secure the tablet press to the workbench using bolts to minimize vibrations.

- Ensure the machine is stable and does not wobble during operation.

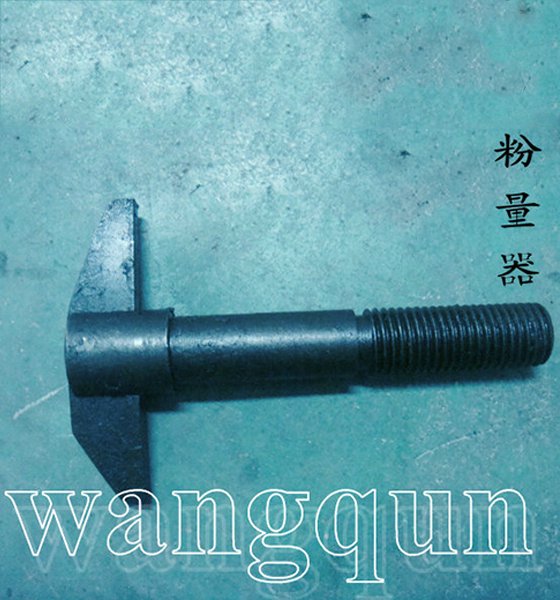

3.2 Installing Punches and Dies

1. Clean the tooling – Remove any protective oil or debris from punches and dies.

2. Insert the lower punch – Place it into the die hole and ensure smooth movement.

3. Install the die – Secure it in the die table using the provided locking mechanism.

4. Insert the upper punch – Align it with the die and ensure proper fit.

5. Check alignment – Manually rotate the turret to confirm smooth operation without binding.

3.3 Feeding System Setup

- Attach the hopper to the feeding frame.

- Ensure the feeder paddle rotates smoothly to distribute powder evenly.

- Adjust the feed depth to control material flow.

3.4 Electrical Connections

- Connect the power cable to a grounded outlet.

- Verify that the control panel is functioning correctly.

---

4. Calibration and Testing

4.1 Lubrication

- Apply food-grade lubricant to moving parts (e.g., turret, guide rails).

- Avoid over-lubrication to prevent contamination.

4.2 Test Run Without Material

- Power on the machine and run it at low speed.

- Listen for unusual noises or vibrations.

- Check punch and die movement for smooth operation.

4.3 Adjusting Tablet Hardness and Thickness

1. Set compression force – Adjust the main compression roller to achieve desired tablet hardness.

2. Control tablet thickness – Modify the lower punch height to change tablet weight and thickness.

3. Test with material – Run a small batch and measure tablet weight, hardness, and disintegration time.

4.4 Troubleshooting Common Issues

| Issue | Possible Cause | Solution |

|-----------|------------------|--------------|

| Uneven tablet weight | Poor powder flow, misaligned feeder | Adjust feed depth, ensure uniform powder distribution |

| Capping or sticking | Excessive moisture, improper compression | Dry powder, reduce compression force |

| Machine jamming | Misaligned punches, foreign particles | Clean tooling, realign punches |

---

5. Operation Guidelines

5.1 Loading the Powder

- Fill the hopper with pre-mixed disinfection powder.

- Avoid overfilling to prevent clogging.

5.2 Starting Production

- Gradually increase speed while monitoring tablet quality.

- Regularly check tablet weight and hardness.

5.3 Shutdown Procedure

1. Stop feeding material.

2. Let the machine run until all powder is compressed.

3. Power off and clean residual powder.

---

6. Maintenance and Cleaning

6.1 Daily Maintenance

- Wipe down the machine to remove dust and powder residues.

- Inspect punches and dies for wear or damage.

6.2 Weekly Maintenance

- Lubricate moving parts.

- Check belt tension and alignment.

6.3 Deep Cleaning

- Disassemble tooling and clean with a soft brush and alcohol.

- Sanitize contact surfaces to prevent cross-contamination.

---

7. Safety Precautions

- Always wear gloves and safety goggles.

- Never operate with loose clothing or jewelry.

- Follow lockout/tagout procedures during maintenance.

---

Conclusion

Proper installation and setup of a disinfection tablet press ensure efficient, high-quality production. By following this guide, operators can minimize downtime, extend machine life, and maintain safety standards. Regular maintenance and calibration are essential for consistent performance.

For further assistance, refer to the manufacturer’s manual or consult a technical expert.

End of Guide

телефон

телефон

Комментарий

(0)